Concrete is the second most used material on Earth, right after water. From your foundation to your front steps, the type of concrete you choose matters. At Builders Group Construction, we’ve seen it all and we build it to last.

Almost every construction project uses concrete in some way. You’ll find it in highways, bridges, parking structures, and homes across Dayton. The material does not rust, rot, or burn. This makes it essential for long-term durability and strength.

But here’s what many homeowners don’t realize: not all concrete is the same. Choosing the right mix affects how long your driveway lasts, whether your patio cracks after winter, and if your foundation can handle Ohio’s freeze-thaw cycles.

With 75+ years of combined team experience, we help Dayton homeowners choose wisely. This guide breaks down 26 types of concrete so you can make informed decisions for your next project.

Why Concrete Choice Matters in Dayton

Dayton’s weather presents unique challenges. Heavy rain, snow, and constant freeze-thaw cycles put stress on concrete. Water seeps into small cracks, freezes, expands, and creates bigger problems.

The right concrete type protects against these issues. It saves you money on repairs and extends the life of your project. Whether you’re planning a patio, driveway, or foundation, understanding concrete basics helps you avoid costly mistakes.

Understanding Concrete Basics

Concrete starts with three main ingredients: cement, aggregates, and water. Portland cement acts as the binder. When mixed with water, a chemical reaction called hydration occurs. This process creates the hard surface we recognize.

Aggregates include sand (fine aggregate) and rocks or pebbles (coarse aggregate). Fine aggregate adds volume. Coarse aggregate provides strength to carry heavy loads.

The typical mixing ratio is:

- 10-15% cement

- 60-75% aggregate

- 15-20% water

Admixtures are special chemicals that change concrete properties. They can speed up setting time, improve workability, or add air bubbles for freeze protection.

Standard and Structural Types of Concrete

These concrete types form the backbone of most construction projects. They provide the strength needed for foundations, slabs, and structural walls.

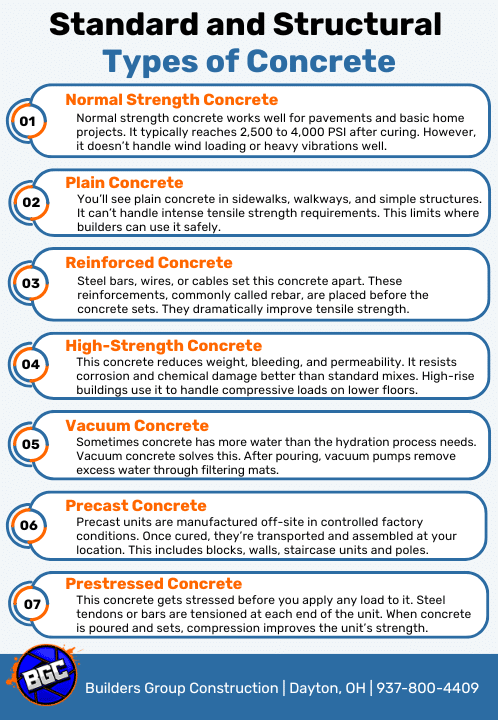

Normal Strength Concrete

This is the most common type you’ll encounter. It uses a basic mix of cement, aggregates, and water in a 1:2:4 ratio. The setting time ranges from 30 to 90 minutes, depending on weather and cement properties.

Normal strength concrete works well for pavements and basic home projects. It typically reaches 2,500 to 4,000 PSI after curing. However, it doesn’t handle wind loading or heavy vibrations well.

Plain Concrete

Plain concrete uses the same mixing proportions as normal strength concrete. The main difference? It contains no reinforcement like rebar or steel bars.

You’ll see plain concrete in sidewalks, walkways, and simple structures. It can’t handle intense tensile strength requirements. This limits where builders can use it safely.

Reinforced Concrete

Steel bars, wires, or cables set this concrete apart. These reinforcements, commonly called rebar, are placed before the concrete sets. They dramatically improve tensile strength.

The combination is powerful. Concrete handles compression forces while steel resists tension. Together, they create structures that withstand enormous loads.

High-Strength Concrete

Any concrete with compressive strength above 6,000 PSI falls into this category. High-strength mixes use durable aggregates, more cement, and less water. Superplasticizers improve workability despite the sticky consistency.

This concrete reduces weight, bleeding, and permeability. It resists corrosion and chemical damage better than standard mixes. High-rise buildings use it to handle compressive loads on lower floors.

High-Performance Concrete

All high-strength concrete can be high-performance, but not all high-performance concrete needs high strength. HPC meets specific standards for placement ease, durability, mechanical properties, and environmental impact.

The focus is on long-term performance. HPC maintains its properties over decades, not just years. Civil projects and commercial buildings benefit most from this investment.

Precast Concrete

Precast units are manufactured off-site in controlled factory conditions. Once cured, they’re transported and assembled at your location. This includes concrete blocks, walls, staircase units, and poles.

Prestressed Concrete

This concrete gets stressed before you apply any load to it. Steel tendons or bars are tensioned at each end of the unit. When concrete is poured and sets, compression improves the unit’s strength.

Prestressed concrete handles heavy loads and long spans better than regular concrete. You’ll find it in bridges, large roofs, and structures carrying significant weight.

Vacuum Concrete

Sometimes concrete has more water than the hydration process needs. Vacuum concrete solves this. After pouring, vacuum pumps remove excess water through filtering mats.

This lowers the water-cement ratio, increasing strength and durability. The concrete also becomes workable sooner. Bridge deck slabs, parking lots, and industrial floors benefit from this technique.

Residential and Decorative Concrete Options

These concrete types focus on appearance and functionality for homes. They’re perfect for patios, driveways, and interior spaces where looks matter.

Stamped Concrete

Also called imprinted or textured concrete, stamped concrete mimics natural stone, tile, brick, or granite. Professional stamping pads create realistic patterns on the concrete surface.

We use stamped concrete for pool decks, patios, interior floors, and driveways. Color stains and texture work add natural finishes. The result looks premium without the cost of real stone pavers.

Benefits include easy maintenance once sealed, slip resistance with additives, and extensive design choices. It adds value to your property while staying budget-friendly.

Glass Concrete

Recycled glass replaces some or all aggregates in this mix. Glass pieces range from fine powder to six-inch rocks. The result has a shiny, glowing appearance.

Decorative Concrete

This category includes any concrete enhanced through coloring, molding, polishing, etching, or special toppings. The goal is to create visual appeal while maintaining functionality.

Swimming pools, accent walls, and feature floors use decorative concrete. It transforms plain surfaces into focal points. If you want personality in your space, this is your answer.

Limecrete

Limecrete replaces cement with lime and uses lightweight aggregates like glass fiber or sharp sand. It’s mainly used for floors, vaults, and domes.

The environmental benefits make it appealing. Limecrete is renewable and easy to clean. It also works well with radiant floor heating systems.

Self-Consolidating Concrete

This concrete flows and settles on its own weight. No vibration or mechanical help needed. It has high filling ability, passes around tight spaces easily, and resists segregation.

The fluidity comes from more fine aggregate and special additives like superplasticizers. This makes self-consolidating concrete ideal for areas with thick reinforcement or complex forms.

Air-Entrained Concrete

Microscopic air bubbles fill this concrete, creating billions of tiny chambers per cubic foot. These pockets let water expand when it freezes, preventing cracks.

Foaming agents added during mixing create the air pockets. They make up 3% to 6% of the total volume. Almost all concrete in freeze-thaw climates like Dayton should be air-entrained.

We recommend air-entrained mixes for any outdoor project. Ohio winters demand this protection to keep your concrete intact year after year.

Fast-Set and Easy-Pour Solutions

Time matters on construction sites. These concrete types speed up projects without sacrificing quality.

Rapid Set Concrete

This concrete hardens within one to several hours instead of the usual 48 hours. Higher cement content and special admixtures accelerate hydration and setting.

Rapid set concrete comes premixed and ready to use. It’s perfect for repair jobs, steps, garage floors, and projects on tight deadlines. We use it when homeowners need quick turnarounds.

Self-Compacting Concrete

Similar to self-consolidating concrete, this mix fills formwork and spreads easily. It encapsulates reinforcement without needing vibration. The material levels itself as it’s poured.

Ready Mix Concrete

Ready mix concrete arrives at your site fully prepared in a truck mixer. No on-site mixing required. It’s batched at a central plant following precise specifications.

The trucks keep the concrete moving during transport. Retarding agents prevent premature hardening on long drives. This is our go-to for driveways, foundations, and large slabs.

Volumetric Concrete

These specialized trucks carry dry ingredients and water separately. Mixing happens at your construction site. This solves problems when sites are far from batching plants.

One truck can produce different mixes for the same project. You might need 4,000 PSI concrete for one area and 3,000 PSI for another. Volumetric trucks handle both.

Large sites, basements, and multi-phase projects use volumetric concrete. It offers flexibility that ready-mix can’t match.

Dry Mix Concrete

For small projects, dry mix concrete makes sense. The cement, sand, and aggregate come pre-mixed in bags. You just add water on-site and mix.

Homeowners use this for fence posts, small repairs, and DIY projects. It’s not practical for large areas but perfect for minor fixes.

Shotcrete Concrete

Shotcrete gets sprayed through a nozzle onto a surface. High air pressure shoots it into place and compacts it simultaneously. This application method makes it unique.

It’s ideal for repairing damaged structures or working in hard-to-reach areas. Formwork isn’t always necessary. Shotcrete adheres to vertical and overhead surfaces easily.

Eco-Friendly and Smart Concrete Types

These innovative concrete types address environmental concerns and future technology needs.

Pervious Concrete

This porous concrete lets water pass through to groundwater below. Little to no fine aggregate creates open spaces for drainage.

Smart Concrete

Short carbon fibers added to regular concrete make it “smart.” These fibers change the material’s electrical resistance under strain or stress.

Polymer Concrete

Polymer binders replace Portland cement in this mix. Options include epoxy, polyester, vinyl ester, and acrylic resins. Each type offers different benefits.

Special Use and Infrastructure-Grade Concrete

These concrete types handle extreme conditions and large-scale projects.

Asphalt Concrete

Also known as asphalt or blacktop, this material uses bitumen instead of Portland cement. It’s the surface you drive on every day.

Pumped Concrete

This concrete moves through pipes to reach difficult locations. Very fine aggregates make it flow smoothly. The finer the aggregate, the easier it pumps.

Roll Compacted Concrete

Heavy rollers compact this concrete after placement. You’ll see this on highways carrying large commercial loads. It’s strong, dense, and emits fewer emissions during production.

High-Density Concrete

This concrete serves a very specific purpose: radiation protection. Atomic power plants and similar facilities require it.

Understanding Concrete Grades and PSI Requirements

PSI (pounds per square inch) measures concrete’s compressive strength. Different projects require different strengths.

C7-C15 (1,000-2,000 PSI): Sidewalks, patios, and light-duty applications. These areas don’t face heavy loads or vehicles.

C20-C30 (2,500-4,000 PSI): Driveways, slabs, and most residential projects. This range handles regular vehicle traffic and typical home use.

C35-C40 (4,500+ PSI): Foundations, garage floors, and heavy-load zones. Dayton’s weather and usage patterns make 4,500 PSI ideal for garage floors.

We recommend 4-inch thickness for standard slabs. Add a 2-3 inch base of gravel or aggregate underneath. For home foundations, pour 8-10 inches at 3,500-4,000 PSI.

Interior floors need minimum 2,500 PSI, but 4,500 PSI is better. Garage floors face heavier wear from vehicles and equipment. The investment in stronger concrete pays off over time.

Real-World Applications for Dayton Homeowners

At BGC, we match concrete types to specific needs. Here’s how we use different mixes:

Foundations: Reinforced concrete at 3,500-4,000 PSI provides the strength your home needs. We pour 8-10 inches and use proper reinforcement for Dayton’s soil conditions.

Patios: Stamped or decorative concrete creates beautiful outdoor spaces. Air-entrainment protects against freeze-thaw damage. We recommend 4-inch thickness at 2,500-4,000 PSI.

Driveways: Ready-mix concrete at 4,000-4,500 PSI handles vehicle traffic. A proper gravel base and adequate thickness prevent cracking.

Interior Floors: Glass concrete or polished finishes transform basements and living spaces. We ensure proper moisture barriers and curing for lasting results.

Commercial Footings: High-density or high-strength mixes support heavy equipment and constant use. Our commercial team has expertise in large-scale applications.

Choosing the Right Concrete for Your Project

Consider these factors when selecting concrete:

Project Type: Foundations need different concrete than patios. Match the mix to the application.

Load Requirements: How much weight will the concrete carry? Vehicles, equipment, and building loads all factor in.

Environmental Exposure: Outdoor concrete faces weather, while indoor concrete doesn’t. Freeze-thaw protection matters in Ohio.

Aesthetic Goals: Do you want plain functionality or visual appeal? Decorative options add personality.

Budget and Timeline: Some concrete types cost more or take longer. Balance your needs with available resources.

Local Conditions: Dayton’s soil, weather, and water table affect concrete performance. Local expertise matters.

Frequently Asked Questions

What’s the difference between concrete and cement?

Cement is one ingredient in concrete. Think of cement as flour in a cake recipe. Concrete is the finished product that includes cement, aggregates, and water mixed together.

How long does concrete take to cure?

Most concrete reaches working strength in 28 days. You can typically walk on it after 24-48 hours. However, it continues gaining strength for months. Rapid-set mixes cure much faster, sometimes in hours.

Why does concrete crack?

Several factors cause cracks. Rapid drying, freeze-thaw cycles, settling ground, excessive loads, and improper installation all contribute. Proper mix selection, thickness, and curing prevent most cracking.

Can concrete be poured in winter?

Yes, but it requires special considerations. Cold weather slows curing. We use admixtures to adjust setting times and protect fresh concrete from freezing. Our team knows how to handle Ohio winters.

How thick should my concrete driveway be?

Four inches is standard for residential driveways, plus a 2-3 inch base layer. Heavy vehicles or RVs may require thicker pours. We evaluate your specific needs during consultation.

What PSI do I need for a garage floor?

We recommend 4,500 PSI for garage floors. This handles vehicle weight, equipment, and wear over time. Lower PSI concrete may crack or deteriorate faster under these conditions.

Is stamped concrete more expensive than regular concrete?

Yes, stamped concrete costs more due to the extra labor and materials. However, it’s less expensive than natural stone or pavers while delivering similar visual appeal. The investment adds significant property value.

How do I maintain my concrete?

Seal outdoor concrete every few years to protect against moisture and stains. Clean regularly with mild soap and water. Avoid harsh chemicals and deicing salts when possible. Repair small cracks promptly to prevent growth.

What’s the best concrete for freeze-thaw climates?

Air-entrained concrete performs best in areas like Dayton. The microscopic air bubbles give water room to expand when freezing. This prevents cracking and extends concrete life significantly.

Can I DIY my concrete project?

Small projects like fence posts or minor repairs work for DIY. Larger projects like driveways, foundations, or patios need professional expertise. Proper grading, mixing, pouring, and finishing require experience and equipment.

Get Started with BGC Today

Not sure which mix suits your driveway or patio? Schedule a free consultation with our team. We’ll visit your site, discuss your vision, and provide transparent pricing.

From stamped patios to structural foundations, BGC builds it better and stronger. Our commitment to 110% client satisfaction means we don’t consider the job done until you’re completely happy.

Contact us at 937-800-4409 or Info@bgcnow.us. Visit https://bgcnow.us to explore our services and see completed projects across Dayton, Beavercreek, Centerville, Kettering, and 20+ surrounding communities.

Experience. Quality. Reliability. That’s the BGC promise. Let’s build something amazing together.